Inside Kaldewei: The birth of a bathtub

Whether private builder, architect or hotelier: the special properties of steel enamel are appreciated worldwide.

Photo: Kaldewei Background: Kaldewei, Evelyn Dragan

Steel

enamel – this special combination of glass and steel is a time-honoured

tradition to which Kaldewei has been devoted with a passion which now extends

across four generations.

Throughout

its 100-year corporate history, the bathroom manufacturer has consistently

pushed the boundaries to improve this material and its manufacturing processes.

Today, steel enamel is a high-tech material, whicht is used worldwide. Especially

for the bathroom, unique objects can be created from robust steel and superior

enamel.

From natural resources to enamel

The raw materials used to produce the enamel are

sourced from six continents.

Kaldewei, Evelyn Dragan

Californian

borax, Scandinavian feldspar, quartz and soda – these and other natural

substances have been the ingredients used for millennia to produce enamel.

Kaldewei has steadily advanced, refined and optimised the unique formula and today

is the only bathroom manufacturer worldwide to produce its enamel in its own

melting furnaces – based on a top-secret proprietary formula.

The

raw materials are mixed in rotary furnaces heated to around 1,300°C. The

resulting red-hot enamel mass is then quenched in cold water causing it to

solidify before it is broken down into tiny glass granules, known as enamel

frit. In rotating ball mills, the enamel frit is mixed with water, additives and

pigments to create a sprayable enamel slurry.

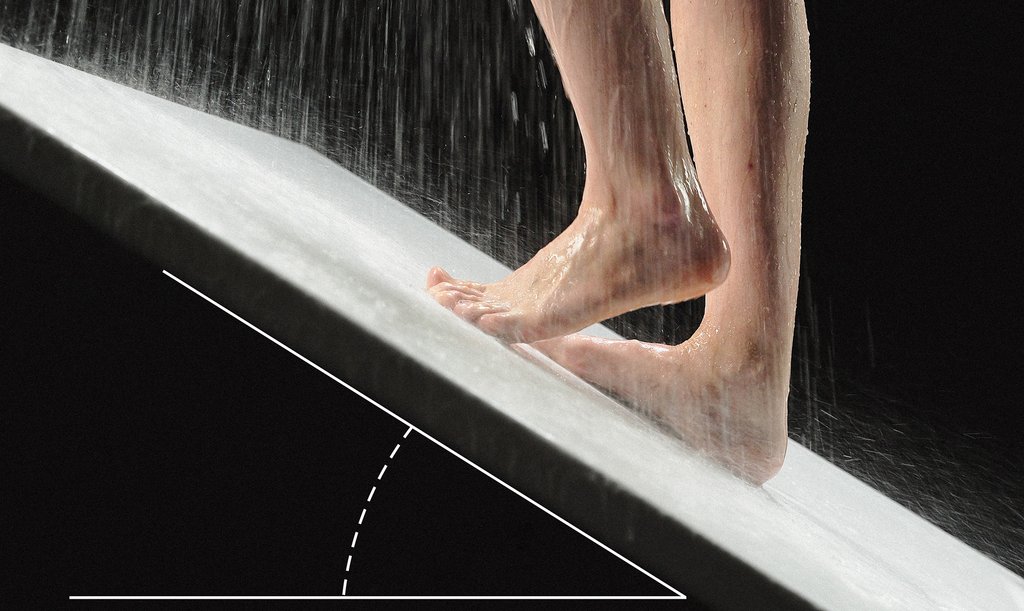

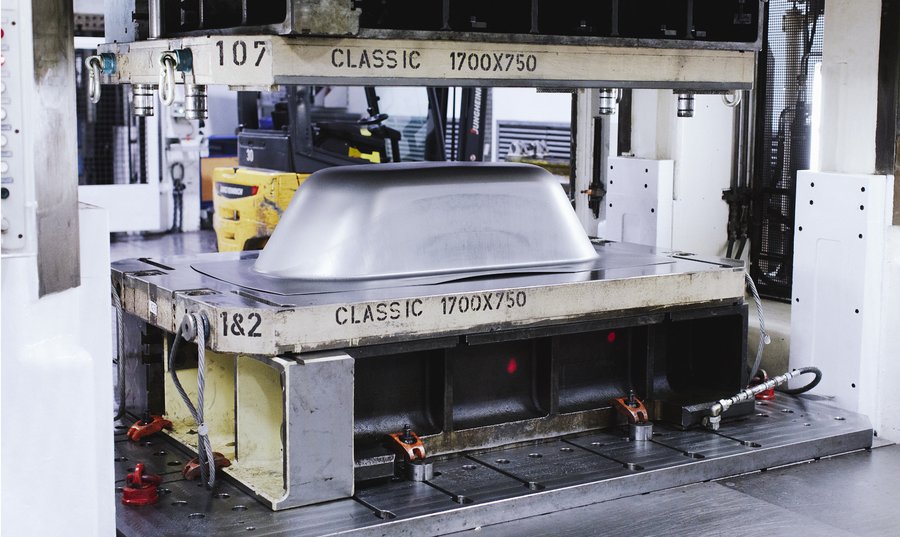

The titanium steel bathtub blank

The bathtubs are formed from a single

sheet of steel by applying forces of up to 1,200 tons.

Kaldewei, Evelyn Dragan

All

Kaldewei bathtub blanks are made from steel of the finest quality, which must be

sufficiently ductile for deep drawing and moulding, while being suitable for

enamelling. In the first step, the micro-alloyed titanium steel blank is deep-drawn

into its ultimate shape on a bathtub press line that applies forces of up to 1,200

tons. Next, the waste and overflow holes are cut in a partly automated process,

and the earthing and transport straps and bath lugs for the feet are welded on.

Custom holes for handles, fittings or whirlpool jets are added by way of laser

drilling.

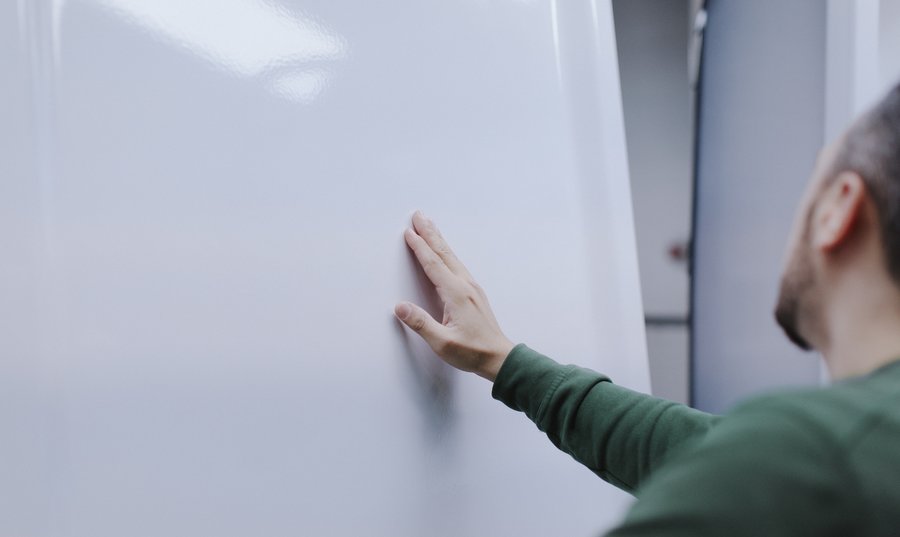

Steel enamel: bonded for eternity

In U-type furnaces, the enamel is fired into the

surface at around 850°C.

Kaldewei, Evelyn Dragan

Steel

and enamel now need to be permanently bonded. In this process, the base coat is

sprayed onto the blanks by robots and fired into the surface at around 850°C. Steel

and enamel form a molecular bond that cannot be mechanically separated and protects

the whole tub body. The final coat provides the enamelled product with its

visual and haptic properties and the needful durability. Steel and enamel have

now formed the inseparable bond that makes the bathtub, shower surface or

washbasin complete.

Long life and rebirth

Every single product undergoes

rigorous quality control testing.

Kaldewei, Evelyn Dragan

Every

bathtub undergoes rigorous quality control testing before leaving the Kaldewei

factory and is released for sale only after it has successfully passed the

inspection. This applies to every bathtub, shower surface and washbasin – without

exception. The unique material quality is backed by the company with a 30-year

guarantee on its products and because all bathroom solutions are produced from

pure, natural resources, they can be fully recycled at the end of their lives –

ready, perhaps, to resurface as a brand-new bathtub.