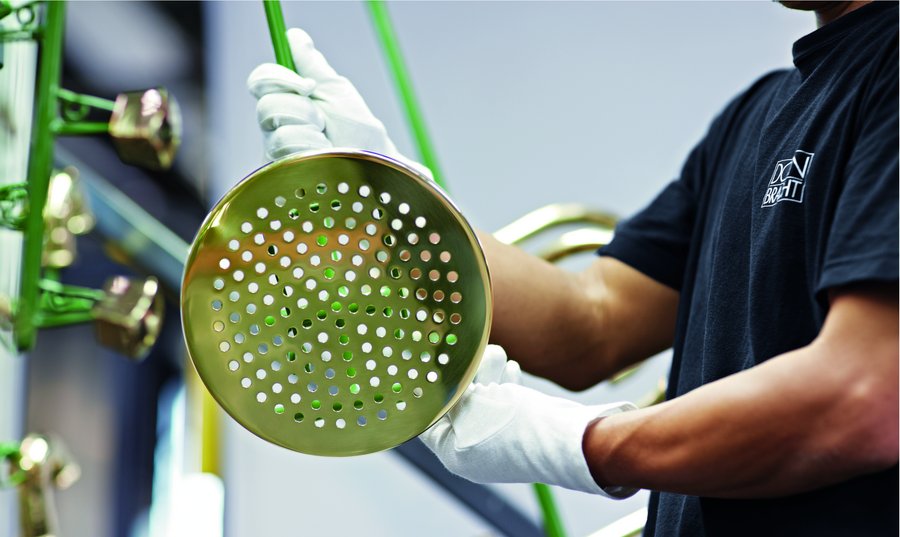

Inside Dornbracht: Traditional craftsmanship and digital technology

All photos: Dornbracht

Iserlohn is the largest city in the Sauerland

region (North Rhine-Westphalia, Germany) and has been shaped by metal

processing since the Middle Ages. The Dornbracht family

business is located here. Even in the age of technology

and digitalisation, the manufacturer of fittings continues to rely on manual

work in large parts of the production in line with a long-standing tradition -

but without losing sight of topics such as digitalisation in the area of conflict

between traditional craftsmanship and innovative technology.

High-tech and handcraft do not have to be incompatible opposites, they

can also complement each other sensibly.In

Iserlohn, all the production steps take place under one roof: from developing

new product solutions and programming relevant software, to electroplating, to

assembly. And even if the work in the factory is increasingly supported by

machines and industrial robots, the number of employees in production has

remained constant for many years. With good reason. Because every single

product passes through the hands of experienced skilled workers, who feel

almost personally responsible for “their” fitting – one of the most reliable

forms of quality assurance. And for the company it has always been one of the most reliable

forms of quality assurance.

Made in Germany – Made in Sauerland

At Dornbracht, production means a lot of manual work in all areas and in almost every step of the manufacturing process.

“There can be no compromise in the premium segment, where we

do our business”, says Andreas Dornbracht, who is in charge of strategy,

finances, communication and marketing. This also applies to the label “Made in

Germany”, which is for Dornbracht both a statement of origin and a promise of

quality. The company not only manufactures in Germany, it also works almost

exclusively with suppliers local to Iserlohn – many of which are also

family companies with a long history. Stable business relationships with tried

and trusted partners from the Sauerland region, more than 60 years’

experience in the industry and the know-how of employees are one of the

cornerstones of the company‘s philosophy.

Therefore, not only highly specialised machines are used in production, it

is above all the knowledge of long-standing employees that counts - because

they have a lot of experience and a highly practised eye, of

course. Every single product is meticulously inspected and examined during its

production, with precision and professionalism. This means that a great deal of

manual work is brought to bear in almost every stage of manufacturing: in

finishing, grinding and polishing just as much as after the plating process, in

assembly – and in detailed checks after every step.

Quality before quantity

Dornbracht manufactures in Germany and works almost

exclusively with local suppliers.

To this day, relatively small quantities and even single pieces

are manufactured at Dornbracht, in response to individual

customer requests. “Neither a single radius nor a single edge will be changed

in our fittings for the sake of producing more items per unit time”, explains

Matthias Dornbracht, who is responsible in the company for developing systems

and technologies. Reaffirming the uncompromising standard we apply to

workmanship, functionality and design. Quality takes precedence over quantity -

and so there is no assembly line or piecework in the production halls

at Dornbracht.

For all the closeness to traditional craftsmanship Dornbracht

has long since moved into the digital age as well. The company presented it‘s

first digital product solutions for bathroom and kitchen in 2010, with the

Ambiance Tuning Technology (ATT). The digital portfolio was enhanced as early

as 2013, with the launch of Smart Water around the shower experienceSensory Sky ,

the electronically controlled Foot Bath and the intelligent kitchen

fitting eUnit Kitchen. In the second six months of 2019, the multi-sensory AquamoonATTshower

was launched onto the market – a response to the pursuit of holistic

well-being. Just tap the touch-screen to experience unique choreographies of

water, flow modes, mood lighting and fragrance. The control elements –

so-called Smart Tools – and the accompanying hardware and software are also

developed in the factory at Iserlohn.

Complementing not contradicting

To this day, relatively small quantities and even single pieces

are manufactured at Dornbracht.

Andreas Dornbracht finds nothing contradictory about the

quality of manufacturing by hand and technological progress. “We are already

surrounded by digitality every single day. It is not a question of whether

high-tech and manual work can be compatible – they have to be. As leading

innovators in premium fittings, we have spent years dealing with the question

of how to reconcile traditional craftsmanship with technology – and in

particular additional digital value.” So the Smart Water technology is not

competing with fittings that are hand made, it represents their logical

development and completion. The equation is a simple one: Craftsmanship +

digital technology = fit for the future.

And the future means meeting the growing need for individualisation. For example, through digital solutions that can be used to select

personalised shower scenarios at the touch of a button. Manufacture

production also complies with the pursuit of individuality, as handmade

products are more likely to meet personal wants and needs than mass production.